Different Types of Fin Tubes Based on Design

There are various types of fin tubes available for heat transfer applications, each uniquely designed with specific dependencies. Each type of fin tube has its advantages and disadvantages in specific applications to be used in the most suitable conditions.

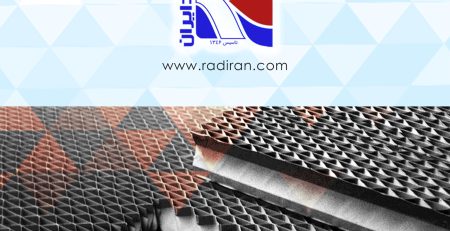

Different Types of Fin Tubes Based on Type of Fin

- Fin Plate

- Wrap-on Fin

- Extruded Fin

Fin Plates

The plate heat exchanger is a type of heat exchanger that uses plates to transfer heat between fluids. In most cases, the plate fin is categorized as a compact heat exchanger, emphasizing its relatively high heat transfer surface compared to its volume. Plate heat exchangers are widely used in the aerospace industry for their compact size and lightweight properties, taking advantage of their ability to facilitate heat transfer with small temperature differences.

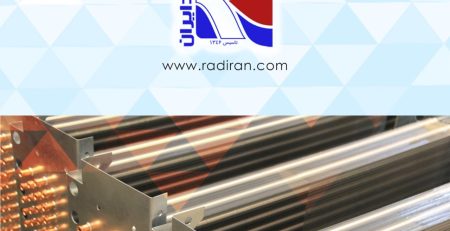

Twisted Fins

In this type of tube, strips made of aluminum, copper, or steel are wrapped around the tubes, and typically, both ends of the fin are connected to the tube. There are various types, including:

- Embedded “G”

- L2

- Knurled “L”

- KL

- Double “L”

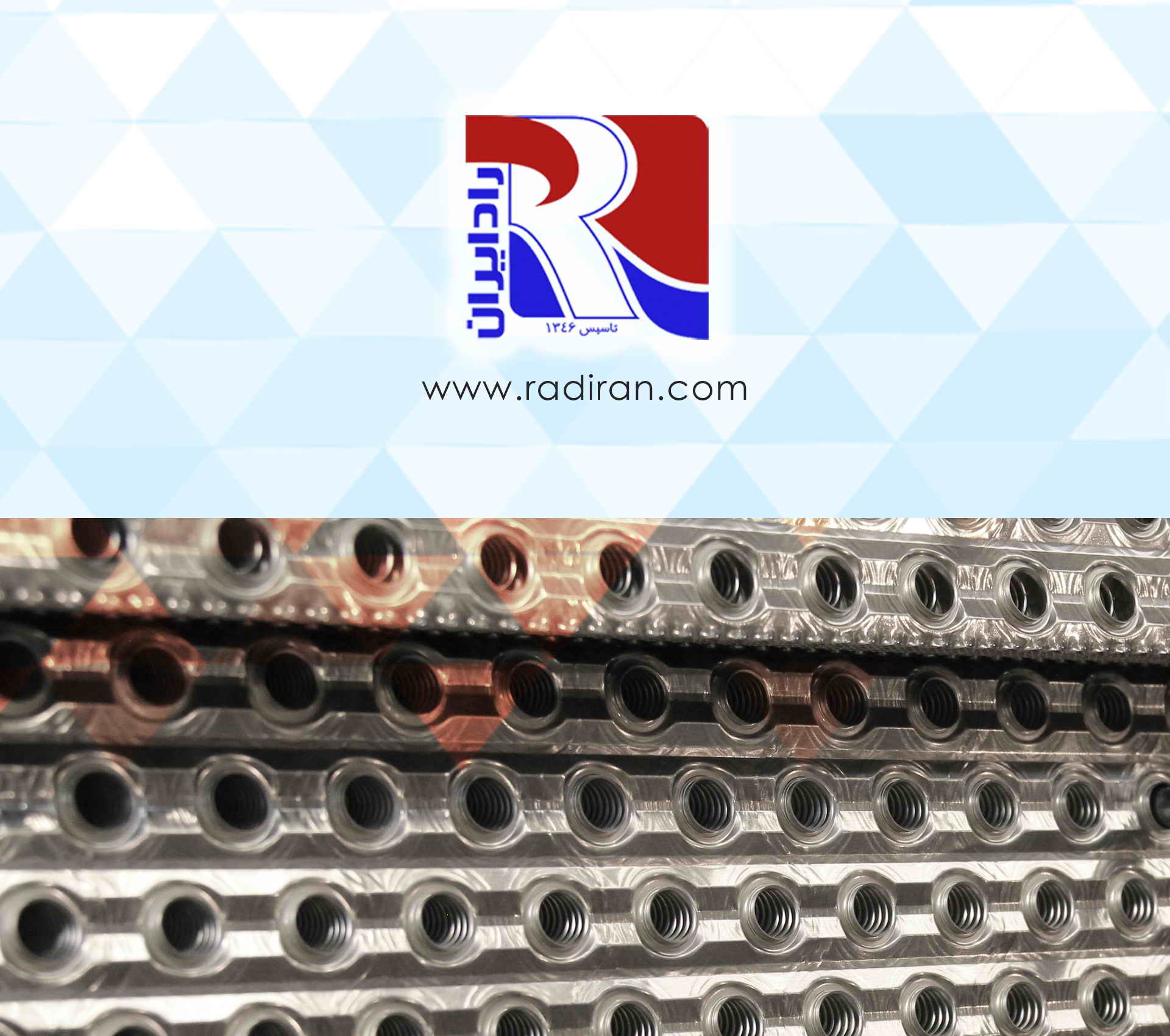

Extruded Fins

Extruded fin tubes come in various types, and the tube material can be of any kind, but the fins can only be made of copper or aluminum. Copper fins are not widely used in the industry due to their high cost.

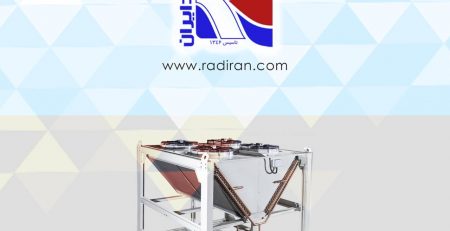

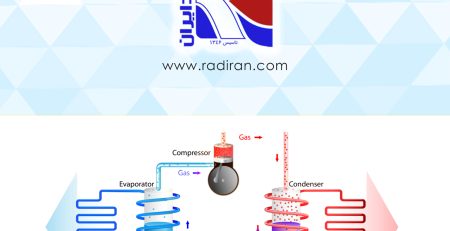

Various Applications of Fin Tubes

Fin tubes are used to transfer heat from hot liquids to cooler fluids through the tube wall. Manufacturers produce a wide range of these tubes, and during the production of fin tubes, a corrosion protection process is carried out, ensuring that the material used in the tubes is corrosion-resistant.

They are used as heat exchangers (cooled with air, water, and chemicals) in various industries, including oil, petrochemicals, steel, electricity generation, and many others.

Fin tubes also have applications in other industries, such as:

- Gas

- Oil

- Petrochemicals

- Power generation

- Food industry

Fin tubes require connecting pipes that can carry heat for effective heat transfer. They are used to transfer heat in types of fin tubes that have an air tube outside, such as radiators, air coolers, and air heaters.

Today, the use of these types of exchangers has significantly increased, especially in developed and advancing countries, where there is an effort to utilize these tools across various fields due to their cost-effectiveness. In many countries, fin tubes are used as heating systems in buildings and even greenhouses instead of radiators.